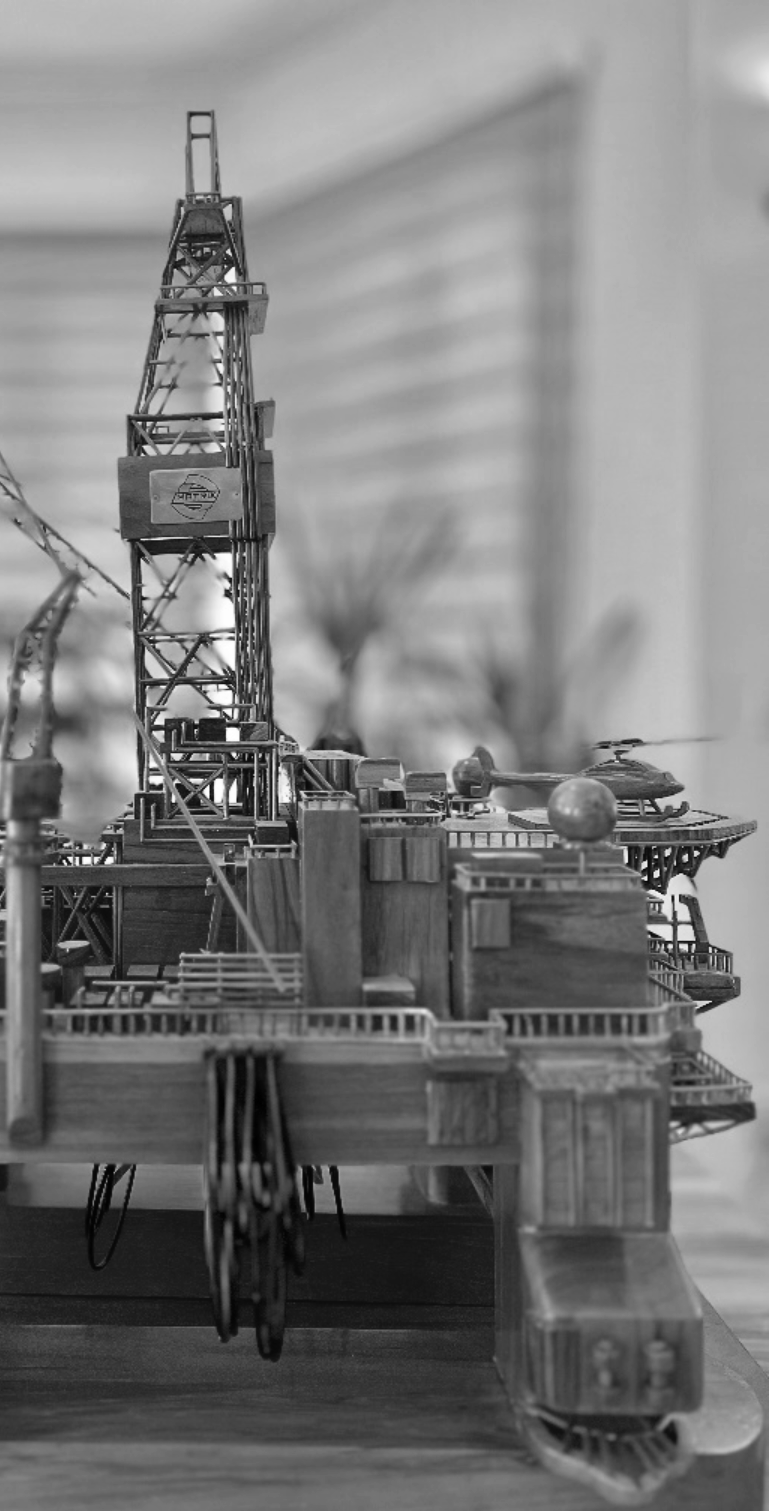

Drilling Fluids

Matrix Drilling Fluids stands tall as a leading provider of comprehensive drilling fluid solutions for the oil and gas industry. With a commitment to excellence and innovation, the company offers a triumvirate of specialized services designed to enhance drilling operations. Our drilling fluids services in matrix employ state-of-the-art methods and technologies to ensure optimal results for our clients. We take pride in delivering high-quality solutions that enhance drilling efficiency, wellbore stability, and overall project success. Below are some of the perfect methods and the results we achieve through our drilling fluids services:

Customized Fluid Formulation: We tailor our drilling fluid formulations to suit the specific geological and operational requirements of each well. Our team of experienced mud engineers analyzes the matrix and designs custom fluid systems to provide optimal drilling performance.

Advanced Fluid Testing: We conduct comprehensive laboratory testing on drilling fluids to assess their physical and chemical properties. This ensures that the chosen fluid system is well-suited for the specific formation, minimizing formation damage and maximizing the drilling rate.

Real-time Monitoring and Analysis: Our drilling fluids services incorporate real-time monitoring and data analysis. We use advanced sensors and monitoring equipment to continuously assess drilling parameters, enabling swift adjustments to the drilling fluid properties when necessary.

Environmentally Friendly Solutions: We prioritize environmental stewardship in our drilling fluids services. Our fluid systems are designed to minimize environmental impact while maintaining high drilling efficiency.

Wellbore Stability and Formation Protection: Our drilling fluids are engineered to provide excellent wellbore stability, reducing the risk of hole instability, wellbore collapse, and stuck pipe issues. They also protect the formation from damage, preserving reservoir productivity.

Cuttings Removal and Suspension: Our fluid systems are optimized to efficiently remove drill cuttings from the wellbore and suspend them for proper removal at the surface. This minimizes the risk of hole-cleaning issues and facilitates smooth drilling operations.

Control of Formation Pressure: We carefully manage the density and rheological properties of our drilling fluids to control formation pressures and prevent blowouts or influxes during drilling operations.

Reduced Non-Productive Time (NPT): Our drilling fluids services contribute to decreased NPT by mitigating drilling challenges, optimizing drilling rate, and minimizing equipment failures related to fluid-related issues.

Skilled and Responsive Technical Support: Our team of experts provides continuous technical support throughout the drilling process. They are available 24/7 to address any operational challenges and make necessary adjustments to the drilling fluid program.

Cost-Effectiveness: Our drilling fluids services are designed to optimize drilling efficiency, reduce operational costs, and maximize the return on investment for our clients.

Matrix Drilling Fluids’ Services are categorized into three main fields: Engineering Services, Solid Control Equipment, and Mud Products.

A Quick Look

Engineering services

Designing and Programming Drilling fluids

Engineering and Monitoring

Reporting

Mud products

Equipment

Solid Control Equipment

. Decanting Centrifuge

+ 518 HV Centrifuge

+ HV FH Centrifuge

+ 414 Centrifuge

. Pumps

+ Feed Pumps

+ Mono Pumps

+ Diesel-Driven Centrifugal Pump

. Shale Shaker

. Mud cleaner

. Sumpless drilling equipment

+ High-G Drying shaker

+ Augers

+ 3-side cutting tanks

+ Cutting skip

. Filtration

+ Dual Pod Filtration Unit

+ DE-Filter Press

. Screen and Filter Cartridge

Waste Management Equipment

. Oil Sludge Treatment Plant

. Dewatering System (Zero discharge)

. Evaporator

. Boiler

. Oil skimmer

. Super vacuum pumps

. Zero discharge

Mud Plant

. Mud tank

. Shear Hopper

. Centrifugal Pump

. Mud Gun

. Agitator

. Bulk silo