Engineering services

Matrix Drilling Fluids prides itself on its expertise in delivering top-notch engineering services tailored to meet the unique needs of each drilling project. The company’s team of skilled managers and engineers collaborates closely with clients to design customized fluid systems that optimize drilling performance and mitigate challenges. Matrix engineering services can be categorized into three main sectors below:

Designing and Programming Drilling fluids

Matrix’s engineering and technical team crafts drilling fluid formulations that strike the perfect balance between stability, lubricity, and compatibility with the formation. Through extensive research and development, they tailor fluids to adapt to diverse wellbore conditions.

Some of these special mud systems are as below:

MMO Mud (Mixed Metal Oxide Mud)

MMO-mud, or mixed metal oxide mud is a high thixotropic mud with enormous benefits for drilling fractured formations and high loss zones. MMO mud was run successfully in the Kurdistan region of Iraq by our team. Our team gained valuable experience in treating formation losses and reducing drilling costs. Matrix Co. is proud to have all the materials, knowledge, and testing equipment to design and run the MMO mud system.

High-Performance Polyamine mud

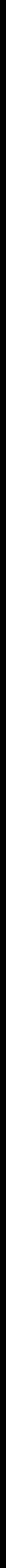

Matrix drilling fluids provide high-performance Polyamine mud for shaly formation to minimize the shale swelling and enhance the hole stability in problematic formations. Polyamine compounds are commonly used as shale inhibitors in drilling fluids to prevent shale dispersion and wellbore instability.

The specific formulation and dosage of the polyamine inhibitor may vary based on the specific geological conditions and drilling requirements of each well. As such, we in Matrix design the most effective drilling fluid system with the appropriate Polyamine concentration to effectively inhibit shale and reduce well cost. From a monitoring point of view, Polyamine concentration is tracked on the location by the Matrix engineering team to ensure the most efficient concentration is applied to save money and resources on drilling fluids.

KCl/Polymer/PHPA mud

Potassium chloride and PHPA (Partially Hydrolyzed Polyacrylamide) are used simultaneously as shale inhibitors in KCL/Polymer/PHPA mud. These two products matched each other significantly and provided acceptable shale inhibition in the drilling fluids system. At Matrix Drilling Fluids, we take pride in our unparalleled professionalism and expertise in formulating Potassium Chloride (KCL) and Partially Hydrolyzed Polyacrylamide (PHPA) drilling fluid additives, tailored to our clients’ specific requirements. With a commitment to excellence and a deep understanding of the drilling process, we deliver custom-made solutions that enhance drilling performance, wellbore integrity, and overall operational efficiency.

RDIF mud

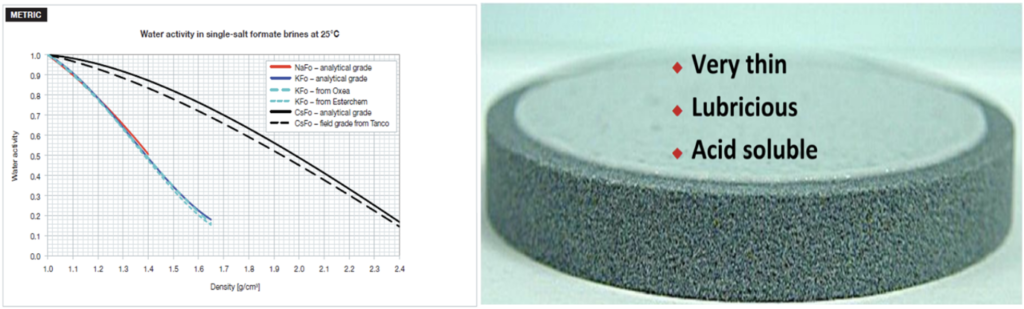

Reservoir Drill-In Fluid (RDIF) is a specific type of drilling fluid used during the drilling of reservoir sections in oil and gas wells. The primary purpose of RDIF is to minimize formation damage and invasion of drilling fluid into the reservoir rock while drilling through the productive formation. This is crucial to ensure that the wellbore remains stable and that the reservoir properties are not negatively impacted during the drilling process. RDIF helps to preserve the reservoir’s porosity and permeability, allowing for efficient hydrocarbon production after the drilling is completed. Matrix is designing RDIF systems by performing experimental research as per formation permeability and other key factors for each single case. The solid part in RDIF mud should have highly acid-soluble properties. Calcium carbonate (different grading) and Micro Max (Manganese Tetroxide Mn3O4) are the most common materials that are being used in RDIF formulations.

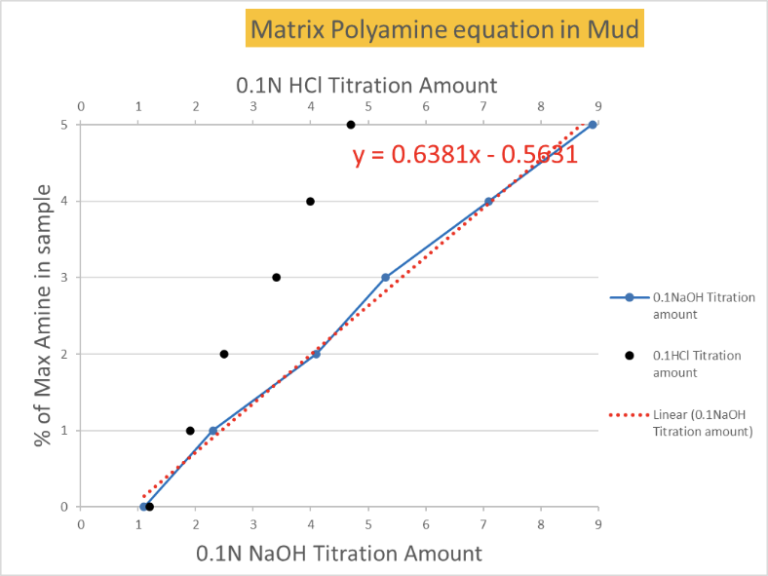

AphronICS System

The water-based Aphron invention control system uses stable energized microbubbles of air to control losses to troublesome formation, when a low-pressure zone is drilled, the Aphrons enter the formation where they expand to equalize formation pressure, effectively protecting the formation from fluid invasion. Standard rig equipment and mixing hopper turbulence are the only requirements for creating the Aphrons and there is no need for an external air source.

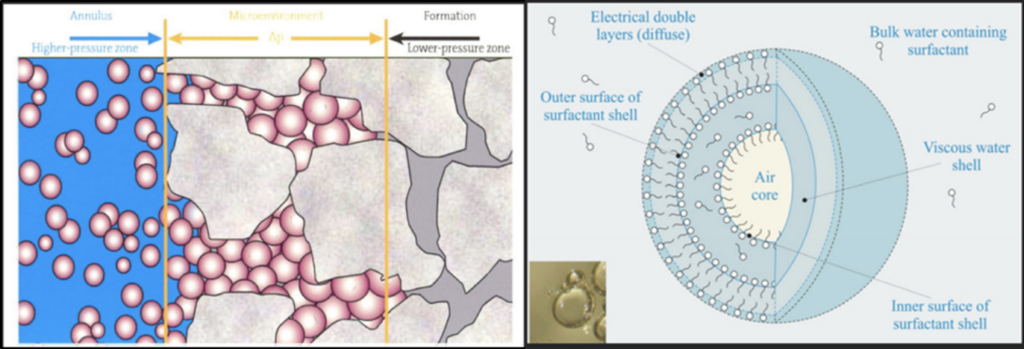

Potassium Formate

Potassium Formate technology is the application of monovalent formate-based brines in drilling and completion operations.

. Advantages

. Minimize formation damage

. Temperature stability up to 175°C

. Formate are excellent hydrate inhibitors

. Low Corrosion Rates

. Provide Lubricity

. Logging interpretation is atypical with formate brines

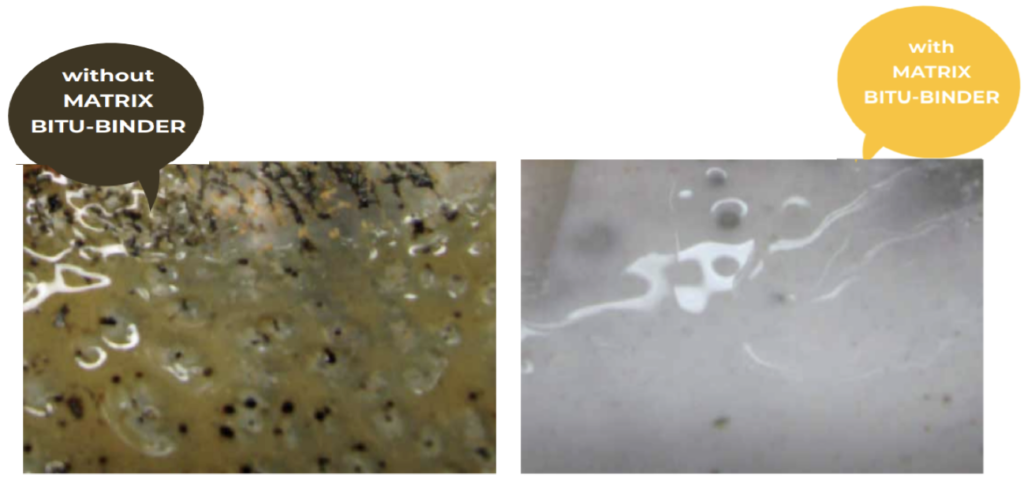

BITU BINDER

Matrix Bitu-Binder prevents Asphaltenes from precipitating from Bitumen. In fact, Matrix Bitu-Binder prevents the oil from even leaving the sand particle. Bitumen remains on the sand. This is accomplished with a simple chemical addition to our clay-free polymer-based mud system.

Advantages:

. Eliminates bitumen accretion

. Minimizes hole washout and prevents hole instability

. No need for excessive drilling waste and surface equipment requirements, including the need for a mud chiller

. Can be easily recycled and reused.

There are different kinds of mud that are designed and performed in Matrix all around Canada and North Iraq. Some of them are as below:

. Glycol Mud systems

. Spud Mud

. Sodium Silicate Mud

. OBM

. SBM

Engineering and Monitoring

it is all about Hydraulics. We have close eyes on Hydraulics on the oil and gas wells as the pivotal means to monitoring the wells. The company’s hydraulic design experts meticulously analyze the well’s parameters to ensure effective hole cleaning, preventing formation damage and increasing drilling efficiency. HYDRO Pro software is used to simulate Hydraulics in the wellbores. This cutting-edge software empowers Matrix engineers to revolutionize their approach to wellbore cleaning. Here are a few advantages of this software:

. Unmatched Precision and Accuracy

. Comprehensive modeling feature

. User-friendly interface

. High-Performance simulation engine

. Visualization and Reporting

Reporting

There is a wide range of reporting software for mud providing a wide range of information on drilling fluids. Here in Matrix, we are using various software for reporting and conveying vital information to our clients. Below there are the software used to provide updated information to our clients:

Technical & Cost Control Power BI Tools

This software enables us to provide drilling companies with comprehensive insights into their technical and cost data. These tools integrate various data sources, such as drilling rig performance, drilling fluids analysis, equipment maintenance, and cost data, into dynamic and interactive dashboards. Through data visualization and drill-down capabilities, drilling professionals can quickly analyze key performance indicators (KPIs), identify trends, and make data-driven decisions to optimize drilling operations, enhance cost efficiency, and improve overall project management. With real-time data updates and automated reporting, Technical & Cost Control Power BI Tools streamline workflows, allowing our clients to efficiently monitor their technical aspects and manage their costs effectively in a highly competitive industry.

Drilling Mud Reporting Software, MUDPRO+

The engineering team on location establishes the Daily Mud Report (DMR) and shares it with clients on a daily basis using MUDPRO+ software. This report includes pivotal information ranging from Rig operation to drilling fluids properties and mud products inventory. One of the salient sections of this reporting system is Hydraulics calculation which provides key information calculated by hydraulics models.

Bridging Software BridgePro